1. Recycled Paper Preparation:

- The process begins with collecting post-consumer paper waste, such as newspapers, magazines or office paper, which is sorted and cleaned to remove any contaminants like ink or staples.

- The cleaned paper is then shredded or pulped into small pieces and mixed with water to create a pulp slurry, resembling a thick soup-like consistency.

2. Blending and Mixing:

- Additional materials may be added to the paper pulp mixture to enhance its texture and strength. This can include cotton fibers, plant fibers or natural dyes for creating variation in colors.

- Depending on the desired thickness and texture of the seed paper, different blending and mixing techniques are employed to achieve the desired consistency.

3. Mold and Deckle Formation:

- The paper pulp mixture is poured into a mold and deckle, a frame with a screen bottom, which helps shape and drain excess water from the pulp.

- The mold and deckle are shaken or tapped gently to distribute the pulp evenly and remove air bubbles, resulting in a smooth and uniform sheet of wet paper.

4. Seed Embedding:

- Once the paper pulp has been evenly distributed in the mold, seeds are added to the mixture. Depending on the desired plant variety, commonly used seeds include wildflower, herb or vegetable seeds.

- The seeds are carefully sprinkled or distributed across the surface of the wet paper pulp, ensuring even distribution and spacing to prevent overcrowding.

5. Pressing and Drying:

- After seed embedding, the wet paper sheet is pressed to remove excess water and compact the pulp fibers together. This can be done using a hydraulic press or mechanical roller system.

- The pressed seed paper is then transferred to a drying rack or conveyor belt, where it undergoes air drying or heat drying processes to remove remaining moisture and solidify the paper.

6. Cutting and Finishing:

- Once completely dry, the seed paper sheets are trimmed and cut into standard business card sizes using a guillotine cutter or die-cutting machine.

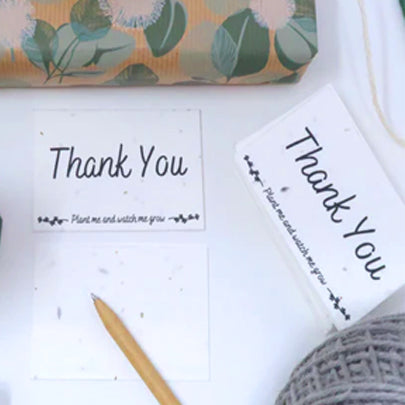

- Additional finishing touches may include rounding the corners, adding custom designs or logos through printing or stamping and packaging the seed paper business cards for distribution.

7. Usage and Planting Instructions:

- Each seed paper business card typically includes planting instructions, encouraging recipients to plant the card in soil after use.

- The planting process involves placing the seed paper card in a pot or garden bed, covering it lightly with soil and watering it regularly until germination occurs.

Conclusion:

Creating seed paper business cards requires a meticulous combination of recycled paper making and seed embedding techniques that result in an eco-friendly and sustainable substitute to traditional business cards. These distinctive cards are made by mixing seeds into the paper pulp, allowing them to not only serve as a memorable marketing tool but also promote environmental consciousness and encourage recipients to participate in the growth of plants and flowers.